DESCRIPTION:

VZR stop-log closures are used wherever it is necessary to cut off the flow or accumulate water. Used as permanent water damming devices or temporary repair closures for surface water, rainwater or sewage in drainage channels and ditches. Made of aluminum, plastic and stainless steel, it is fully weatherproof.

MATERIALS:

Frame: Stainless steel, e.g. AISI 304/304L - 1.4301/1.4307, acid-resistant AISI 316/316L - 1.4401/1.4404 aluminum or any other depending on customer requirements and conditions at the mounting site

Logs: Aluminum, Stainless steel, GRP plastic, Wood or other according to customer requirements.

Gaskets: EPDM (or other material depending on working conditions, e.g. NBR, VITON or silicone).

TIGHTNESS:

Tightness class: class G (2.0mm3/s x DN) acc. PN-EN 12266-1:2012 Tab. A.5 up to the height of the closure.

MOUNTING:

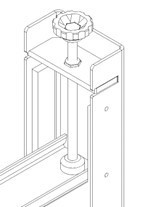

The frame is anchored to the wall and the bottom using anchors. The frame is mounted in grooves in the wall to be filled with concrete or to a flat wall. It is possible to make a frame adapted to installation in a round chamber. The logs are inserted into the vertical guides and then pressed down using compression wrenches in order to compress the seals and ensure the tightness of the system.

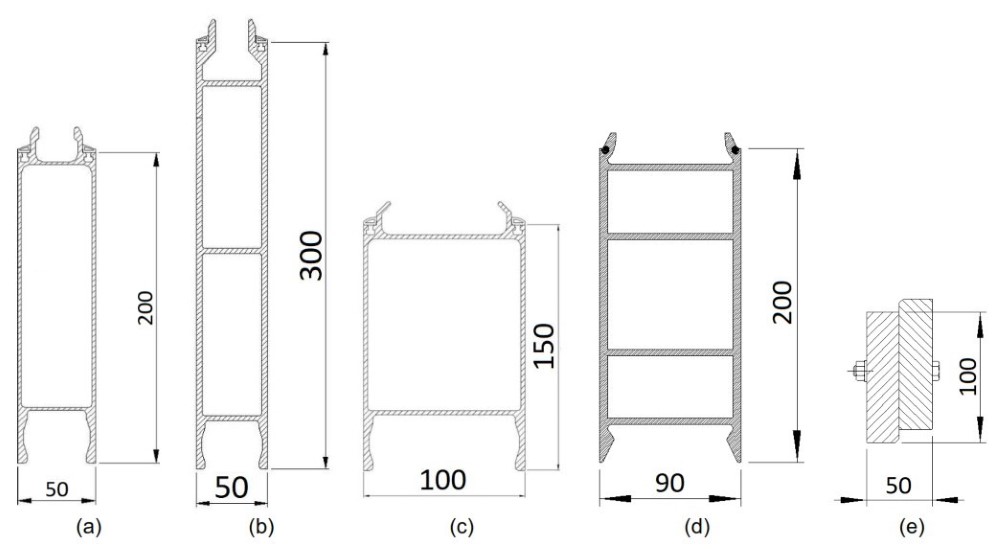

Typy belek szandorowych:

The following standard beam types are available:

- Aluminum beam 50x200

- Aluminum beam 50x300

- Aluminum beam 100x150

- PVC beam 90x200

- PEHD beam 50x100

AVAILABLE OPTIONS:

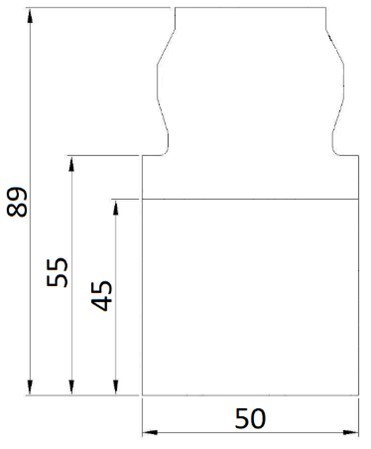

Where it is necessary to provide pressure, compression keys are available mounted in sockets in the guides. The bottom beam is equipped with a bottom seal ensuring tightness and adjusting to any unevenness and impurities on the bottom.

|

|

|

Compression key |

Bottom gasket |

It is possible to make a penstock of any size, adapted to the mounting location. We make stop-log closures with beams connected into panels, with a flow regulator mounted in a panel, with a mechanism for lifting beams, etc.

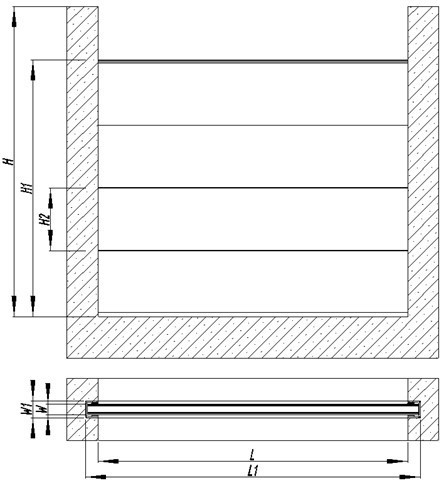

DIMENSIONS:

All gate valves are made for a specific order. Basic dimensions are:

L: Channel width L1: Total width

W: Beam thickness W1: Total thickness

H: Channel height H1: Damming height

H2: Beam height

MOUNTING:

|

|

|

|

Flat channel mounting |

Groove mounting |

Front wall mounting |

DOCUMENTATION:

Standard documentation delivered with the delivery includes: the national declaration of performance, technical and operational documentation along with the operating and assembly instructions. On request, we provide material certificates, welding documents and other according to the customer's needs.

| Data sheet: |